In the quiet hum of a designer’s studio or the gentle rhythm of a crafter’s needle, a subtle revolution is unfolding—one measured in millimeters. At just 1.5 centimeters wide, a delicate thread of creativity is weaving through fashion runways, artisanal accessories, and mindful DIY projects. This isn’t just lace; it’s narrative fabric, where tradition meets innovation, and sustainability dances with style.

When Craftsmanship Meets Contemporary Style

The magic of 1.5cm polyester lace trims lies not in their scale, but in their significance. A whisper-thin border on a bridal veil, a textured accent along a minimalist dress neckline—these small details command attention without demanding it. They are the punctuation marks in the language of design: elegant, intentional, and unforgettable.

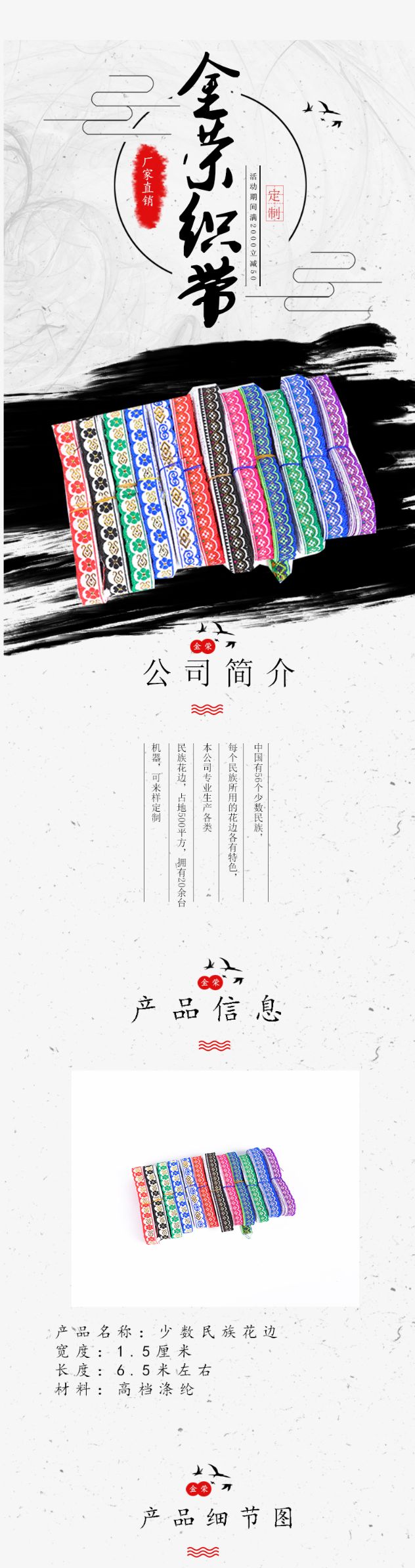

Originally inspired by ancestral textile motifs from minority cultures, these laces reinterpret symbolic patterns through a modern lens. Geometric lines echo ancient storytelling; interwoven symbols pay homage to heritage—all while avoiding appropriation by focusing on abstraction and artistic evolution. Each trim becomes a canvas, carrying cultural resonance in its threads, yet speaking fluently to today’s global aesthetic.

Factory Direct Access: Redefining Supply Chain Intelligence

Gone are the days when only large fashion houses could access premium trims at competitive prices. With factory-direct sourcing, independent designers and small studios now enjoy the same advantages: lower costs, faster turnaround, and greater flexibility in customization.

Bypassing layers of distribution doesn’t just cut expenses—it builds resilience. When you source straight from the production floor, communication improves, lead times shorten, and responsiveness soars. Need a slight color adjustment? Want to test a limited batch before scaling up? These aren't hurdles—they're seamless possibilities.

The Art and Science Behind the Weave

What sets these 1.5cm trims apart isn’t merely appearance—it’s construction. Woven using advanced jacquard technology, each motif emerges organically from the fabric itself, rather than being printed or stitched atop. The result? A tactile depth that holds up under light, movement, and time.

Reinforced with high-density polyester yarns, these webbings resist fraying, fading, and deformation. Unlike flat printed tapes that lose clarity after repeated washes, jacquard embroidery maintains its definition—even after months of wear. Whether used as edging on garments or structural elements in accessories, durability is woven into every inch.

Redefining Creative Possibilities Across Industries

Fashion designers are embracing this narrow lace for its precision and subtlety. Used along sleeve cuffs, hemlines, or décolletage edges, it adds refinement without overwhelming clean silhouettes. In ready-to-wear collections, it elevates basics into statement pieces with minimal intervention.

For accessory brands, the applications multiply. Imagine braided hair ribbons accented with tribal-inspired lace, or brooches where metallic-threaded trims form sculptural centers. Even footwear designers are integrating these webbings into straps and overlays, turning functional components into focal points.

And in the world of mindful making, crafters use them to breathe new life into old garments, journals, and home textiles. Sewn onto denim jackets, glued into scrapbooks, or layered in textile art, each piece tells a story of transformation and personal expression.

Sustainability Woven Into Design

Eco-conscious creation isn’t limited to organic cotton or recycled fibers. True sustainability also means efficiency, longevity, and thoughtful resource use. That’s where 1.5cm polyester lace shines.

Polyester offers exceptional strength and colorfastness, ensuring products last longer and require fewer replacements. Its precise width minimizes cutting waste during manufacturing—a critical factor for zero-waste pattern makers. And because it’s produced in controlled environments with consistent output, over-ordering due to quality inconsistency becomes a thing of the past.

From Vision to Reality: Navigating Sampling and Production

Starting a project with custom lace begins with vision—but grounding that vision in practicality ensures success. For buyers, consider requesting physical samples to evaluate drape, stiffness, and hue accuracy under natural light. Many suppliers offer Pantone matching services, allowing seamless integration into existing color palettes.

Minimum order quantities are often flexible, especially when working directly with manufacturers. Smaller batches reduce risk while enabling experimentation. During inspection, focus on stitch density, edge neatness, and consistency across rolls—small variances can impact final presentation.

The Future of Decorative Trims: Beyond Ornament

As wearable tech and modular fashion gain momentum, decorative trims may soon serve dual roles. Imagine lace-integrated conductive threads powering LED embellishments, or detachable jacquard panels that allow users to customize garment appearances daily.

Today’s 1.5cm polyester lace might become tomorrow’s interface between human and garment—a bridge between beauty and function. As boundaries blur between craft and innovation, one truth remains: the smallest details often carry the biggest meaning.